Hole Punching Machine for PP Honeycomb Panel

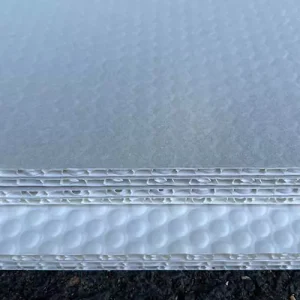

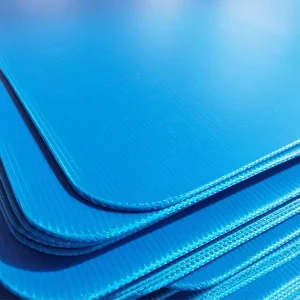

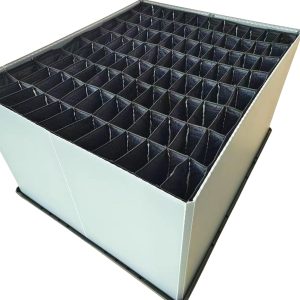

Hole punching machine is designed to punch holes into 8mm-12mm PP honeycomb panel and pp corrugated sheet. pp honeycomb panels are often used in the manufacturing of pallet sleeves.

The purpose of the hole punching machine is to create holes in the PP honeycomb panel that are suitable for adding plastic locks. These sleeves are used to cover the pallets and protect the goods that are being transported on them. The machine is designed to create holes that are precisely positioned and spaced, so that the locks will fit properly at bottom pallet and lid.

Holes at bottom and up the pallet sleeves, also adds locks to the panels. These locks are used to secure the panels with pallet and cover together and create a sturdy and reliable structure for the pallets containers. The locks are also carefully positioned and designed to ensure that the panels fit together perfectly, providing maximum stability and protection for the goods being transported.

The hole punching machine is an important tool in the manufacturing of plastic pallet sleeve. It is designed to create precise holes .

Hole punching machine Features

The hole punching machine is designed to punch 8-12mm PP honeycomb board and PP corrugated sheet. It is made of high-quality durable materials and features a powerful motor which provides plenty of power to punch through the toughest materials, making it perfect for industrial applications. The machine has an adjustable pressure control system, allowing you to adjust the pressure to suit your needs. It can be used for both single and multiple holes and comes with a set of dies for different hole sizes. It also has an adjustable depth stop for precise control of the depth of holes. The machine is easy to operate and comes with a user manual for quick reference.

Plastic Board Hole Punching Machine: An Essential Tool for Industrial Applications

The hole punching machine is a versatile tool designed to make clean and precise holes in a variety of materials, including PP honeycomb board and PP corrugated sheet. It is an essential tool for a wide range of industrial applications, from packaging and signage to construction and automotive manufacturing.

| Raw Materai | All plastic sheet, PP honeycomb panel, pp corrguated sheet, X type pp hollow board |

| Thickness | 4-12mm |

| Max material width | upto 1300mm or custom |

| Pressing time | based on material |

| Operate type | manually/auto |

| Board’s move | auto/manually |

| Structure | Square steel |

| hydraulic system | Pirelli air cylinder |

| Power | 0.7 kw |

| Compressed air | 0.55 |

| Voltage | 380v or custom |

| Size | L1200xW1600xH1700 |

| PLC Control | no |

| Hole size | 100x50mm or cutsom |

| Hole quantity | 2 pcs or 4 pcs / step |

| Working Speed | please check video |