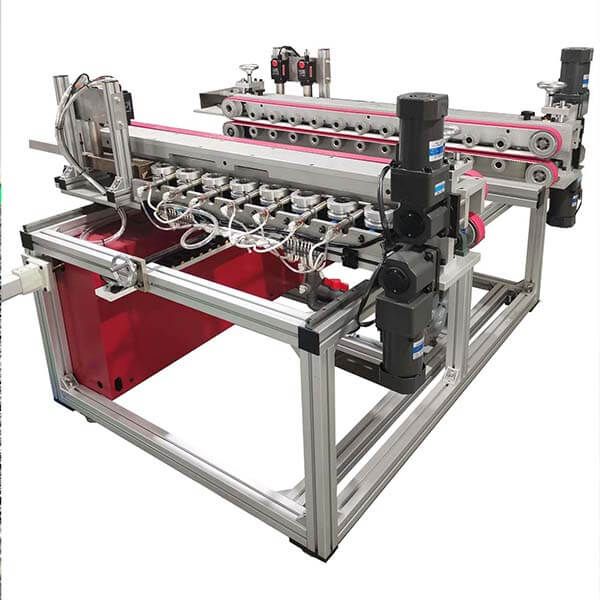

Hollow Plastic Edge Sealing Machine for PP Honeycomb Board

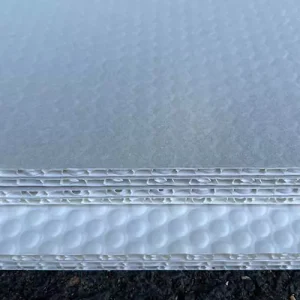

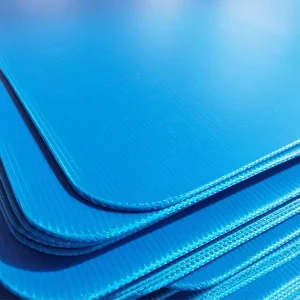

Edge sealing machine for 8-12mm PP honeycomb board is a specialized piece of industrial equipment that is used to seal the edges of honeycomb board made from polypropylene (PP) material. The edge sealing machine uses a hot melt method to seal the edges of the board, which creates a strong, durable bond that prevents moisture and other contaminants from penetrating the board.

This edge sealing equipment is designed to operate at a high speed, which makes it ideal for use in large-scale manufacturing operations. The machine can handle board thicknesses ranging from 8-12mm, which is a common size for many applications.

To use the machine, operators will need to load the board into the machine, and then the machine will automatically hot melt seal the edges of the board. The machine will then use heat and pressure to seal the edges, creating a strong, durable bond in smooth flat or round shape.

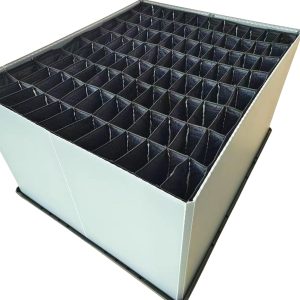

Overall, the high speed hot melt edge sealing machine for 8-12mm PP honeycomb board is a critical piece of equipment for manufacturers who need to produce high-quality sealed edge honeycomb board products at a high volume and with consistent quality

Edge Sealing Machine Features

The machine has a fast operating speed of 1-2 meters per minute, based on 10mm material thickness.

Its fully automatic operation enables businesses to produce large quantities of pallet sleeves quickly, reducing labor costs, and increasing productivity.

The machine provides businesses with the flexibility to choose between round and tip edges, catering to their specific edge type requirements.

The machine employs high-quality sealing technology that ensures tight and secure sealing of pallet sleeves. This sealing technology provides superior protection against damage during transportation.

The machine is designed to be easy to maintain, minimizing downtime and maximizing operational performance.

Each machine one worker is enough. We also offer automatic material loading and unloading equipment at front and end.

| Raw Materai | All plastic sheet, PP honeycomb panel, pp corrguated sheet, X type pp hollow board |

| Thickness | 7-12mm |

| Max material width | 500 -1300mm |

| Width adjustment | manually |

| Material loading | manually/auto |

| Board’s move | auto |

| Structure | Square steel |

| hydraulic system | no |

| Power | 17.0 kw |

| Compressed air | no |

| Voltage | 380v or custom |

| Size | L 5700x W2300xH1100mm |

| PLC Control | no |

| Heating Method | heating bar |

| Sealed Edge Shape | round, flat or pointy |

| Working Speed | please check video |