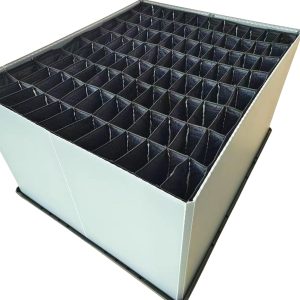

Sleeve Loading Door Making Machine for Pallet Pack Container

Loading door making machine is a specialized equipment designed to produce doors or windows in the PP honeycomb sleeves. These openings would then serve as the “windows” of the container, allowing for visibility and loading of the materials being transported.

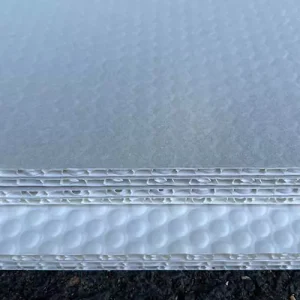

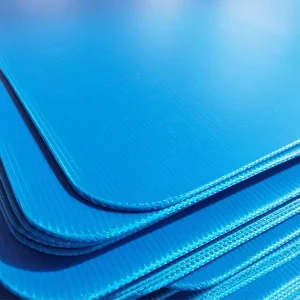

These windows are used in Pallet Pack Container sleeves made of lightweight and durable plastic. The purpose of these containers is to make loading and unloading of materials easier and efficient. These containers are stackable and can be transported by pallet or forklift. The windows provide visibility and ventilation of the materials being transported. These containers are commonly used in industries such as aotumotive, manufacturing, logistics, and storage. Overall, the Loading Door Making Machine is an essential component of the manufacturing process for producing Pallet Pack Container sleeves and boxes that facilitate the loading and unloading of materials.

Loading Door Making Machine Features

The Loading Door Making Machine use hot melt and press-cutting method. The mold and knife can be easily replaced to accommodate various specifications. One major advantage is that the board doesn’t need to be moved after loading, which reduces the likelihood of misalignment and scrapping due to displacement.

| Raw Materai | All plastic sheet, PP honeycomb panel, pp corrguated sheet, X type pp hollow board |

| Thickness | 4-12mm |

| Max material width | upto 1300mm or custom |

| Heating time | based on material |

| Pressing time | based on material |

| Operate type | manually |

| Board’s move | auto/manually |

| Structure | Square steel |

| hydraulic system | Pirelli air cylinder |

| Power | 12.0 kw |

| Compressed air | 0.55 |

| Voltage | 380v or custom |

| Size | L3800xW1600xH2450mm |

| PLC Control | Yes |

| Door/Window size | 600x450mm or cutsom |

| Working Speed | please check video |